My name is Kinga and I’m a second year Design + Change student at Linnaeus university in Växjö. During the last few months I have worked on a project in collaboration with Sagomuseet in Ljungby and in this post I’d like to invite you to learn more about the fun process of storytelling, e-waste and experiments.

So how do design and stories tie together? – well at the core of each great design is an even better story. So for the module focused around the region of Småland I decided to delve deeper and explore the world of local folk stories through the lens of design practice. Later on I also added a lens of electronic waste – in a sense combing the old with the new.

The project is called Fabularum – from Latin the stories belonging to the people – and consists of two parts. The first half invites you into the Småland’s land of legends – Sagobygden, where the local stories live on at the Sagomuseet in Ljungby. For this I designed three story-inspired rings, where engraved visuals become a wearable narrative. Thus the rings aren’t only decorative, they are also portable – and with that portability comes an opportunity to create interest and conversations also outside of the wearer.

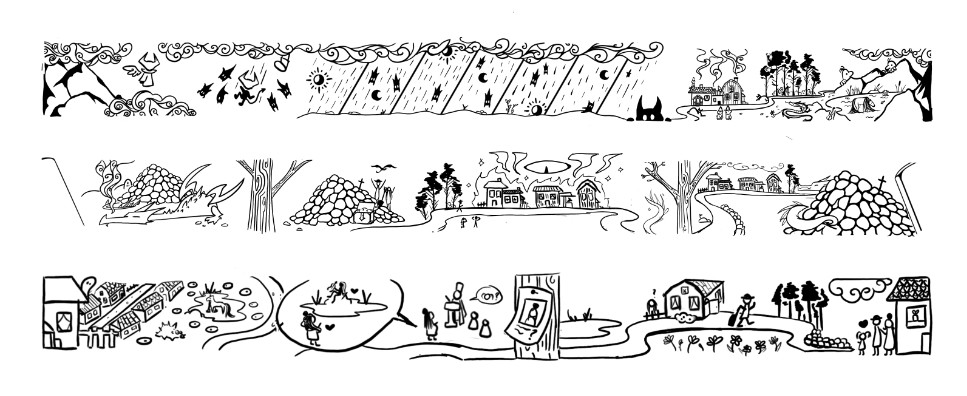

I chosed three local to Småland stories that Lina and Per from Sagomuseet sent to me and preserved them in a form of a visual engraving on the rings. These were supported by packaging designs meant to mimic the appearance of a story book. The stories I chose to work with were: “The devil’s appendage”, which explains the origin of so many folk creatures found around Sagobygden; “The treasure of Högarör”, which I choose partially because of my personal interest in dragons; and “The Maiden Ragnhild and The Neck of Hjärtanäs”, which is a humorous tale about a local Näcken with a bit of a plot-twist.

In order top to bottom: “The devil’s appendage”, “The treasure of Högarör”, “The Maiden Ragnhild and The Neck of Hjärtanäs”. These vector sketches were later embossed onto the ring models.

3D printed ring models of each story-ring. These were later glued onto sprues and used to create casting mould.

The packaging designs for the rings are inspired by story books. Each “book” features the story of the ring as well as short information about the origin of the copper used to make them and a piece of the metal.

The second part of the project dives into e-waste – and how a lack of modularity impacts the amount of unnecessary electronic trash produced worldwide. For this I designed seven beads that are meant to be a part of a necklace or a bracelet. On one side of each bead is a laptop component; on the other, a part of a “modular” story. The computer parts chosen for the beads came from the most well-known parts required to build a PC or a laptop. These include: central processing unit (CPU), graphics processing unit (GPU), random access memory (RAM), motherboard, keyboard, power supply and a display screen.

On the other side of the beads, viewers can see a short story following a robotic dragon as the focal character. The story “modules” include different panels of the dragon’s tale – some more positive, others negative. The viewer is meant to engage with this story as its narrator – literally representing their power to modify and compose their own narrative and by proxy design and repair their own electronics.

The seven story-beads printed in grey resin. As the participant arranges and adds them in various order new variants of the story are created.

Lastly, after all the designing and modelling process, there came a time to test the designs out. I’ll admit I have never metal cast before and the process is fairly difficult, hence the final results look a little different than I expected, but none the less they look very antique and fun. The process of metal casting starts with printing all the models in a castable resin and curing it to harden and keep its shape. After that the model is inserted into a casting flask and submerged in plaster, which creates a mould, into which we can later pour molten metal. The flask is then put into a kiln and the model gets burnt out, leaving a hollow cavity. After that flask gets placed into a vacuum device, and copper gets melted at a staggering temperature of 1150 degrees Celsius (extremely hot). And then we finally pour it in and hope for the best!

On the left a sprue with all the models assembled using jewellery wax. On the right a flask with hardening plaster – as you can see mistakes are part of the process!

Left: cable copper ready to be melted down in a lab furnace. Right: Cast sprue (I was so happy it actually worked)

I was also asked to create a poster for the project, which we later exhibited at Regionshuset in Växjö together with my classmate’s posters.

I’d like to thank Sagomuseet, especially Lina and Per, for providing me with the wonderful stories and inspiration for this project and I hope that you liked the process pictures!

Kinga Kurmanowska